The role of an Aluminum Casting Company in global production processes

Best Practices for Maintenance and Applications in the Aluminum Foundry Industry: A Thorough Summary

Preserving devices in the aluminum factory market is necessary for operational success. Routine assessments and anticipating upkeep can considerably lower downtime and improve safety and security. Advanced modern technologies, such as IoT and information analytics, play an essential duty in this process. Comprehending the full extent of best practices needs a closer examination of details strategies and their effects on efficiency. What are the necessary parts that add to a dependable maintenance structure?

Importance of Routine Maintenance in Aluminum Foundries

Routine maintenance plays a crucial function in the reliable procedure of aluminum foundries. By systematically examining and servicing equipment, shops guarantee peak efficiency and longevity of machinery. Regular upkeep tasks, such as component, cleaning, and lubrication substitute, assistance prevent unforeseen malfunctions that can bring about expensive downtime.

Routine checks boost workplace safety and security by identifying potential hazards before they rise into major concerns. Equipment that is well-maintained runs more successfully, bring about improved item top quality and minimized waste. In addition, adherence to a structured maintenance timetable can sustain compliance with sector regulations, thus fostering a track record for integrity and quality within the market.

Carrying Out Anticipating Upkeep Methods

Anticipating upkeep approaches take the concepts of routine upkeep a step better by leveraging information analytics and progressed surveillance technologies. In light weight aluminum foundries, these strategies enable operators to expect devices failures before they happen, therefore reducing unplanned downtimes and optimizing operational efficiency. By utilizing sensors and IoT devices, real-time data can be collected on machine efficiency, permitting the recognition of possible issues via anticipating analytics.

Maximizing Melting and Putting Procedures

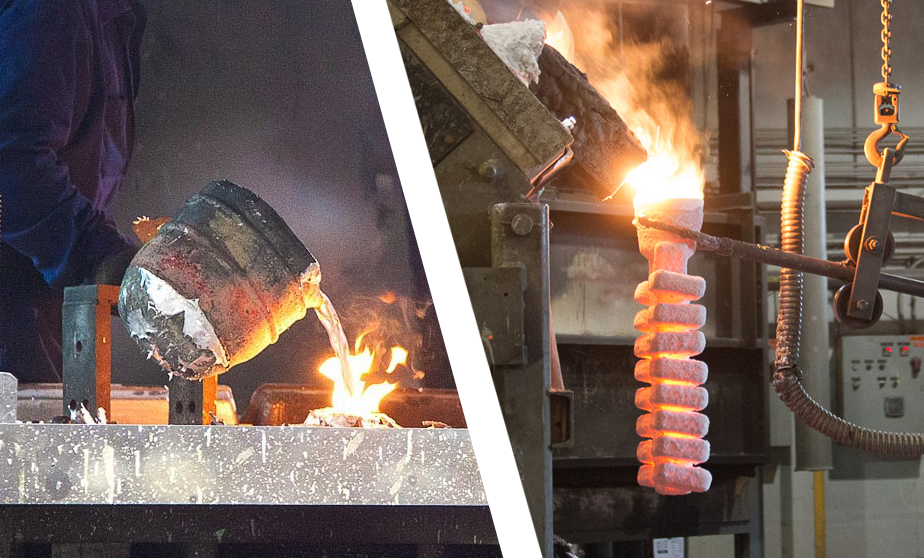

Effective melting and pouring processes are vital for making best use of efficiency and ensuring the high quality of aluminum spreadings. To improve these processes, factories must concentrate on exact temperature control during melting, as this straight influences the metallurgical residential or commercial properties of the alloy. Utilizing advanced melting modern technologies, such as induction and resistance melting, can enhance energy performance and decrease cycle times.

Executing automated putting systems lessens human mistake and keeps consistency in the putting process. Correct mold and mildew preparation, consisting of sufficient preheating, is important to protect against thermal shock and boost mold and mildew longevity.

Enhancing Safety And Security Protocols in Factory Procedures

Focusing on safety in aluminum foundry procedures is essential for protecting workers and ensuring an effective environment. Efficient safety and security methods consist of regular training sessions that stress the significance of individual safety devices (PPE), such as headgears, handwear covers, and safety glasses. In addition, the facility of clear emergency situation treatments is crucial in taking care of possible mishaps.

Routine assessments of devices and machinery help determine risks before they escalate right into significant concerns. Applying a robust reporting system encourages workers to communicate safety and security problems without anxiety of repercussion. Moreover, cultivating a society of safety and security guarantees that every employee recognizes their function in preserving a secure office.

In addition, guaranteeing proper air flow and tracking air quality can minimize exposure to hazardous fumes and dirt. By reinforcing these practices, light weight aluminum foundries can greatly lower the risk of crashes and produce an atmosphere where staff members feel valued and secure, eventually boosting general operational performance.

Leveraging Technology for Improved Performance

Using innovative technology has come to be significantly vital for light weight aluminum foundries aiming to improve functional performance. Automation and robotics play a vital function in improving production processes, reducing labor prices, and lessening her explanation human mistake. Carrying out real-time surveillance systems enables for the continuous evaluation of devices performance, allowing aggressive upkeep and lowering downtime.

Moreover, the integration of data analytics offers useful insights right into functional operations, helping with far better decision-making and resource allocation. For instance, predictive analytics can identify possible failures before they occur, additional maximizing upkeep timetables.

Additionally, taking on sophisticated melting and casting technologies boosts power performance and product yield, which are basic for sustainability in the market. By accepting these technical innovations, light weight aluminum factories can not only enhance efficiency but additionally preserve an one-upmanship in a progressively demanding market (Aluminum Casting). Inevitably, leveraging innovation is pivotal in driving technology and improving overall functional effectiveness within the market

Frequently Asked Inquiries

What Prevail Signs of Devices Wear in Aluminum Foundries?

Common indicators of equipment wear in aluminum shops include unusual sounds, decreased effectiveness, increased resonance, overheating components, leakages, and noticeable corrosion. These signs frequently indicate the requirement for maintenance or possible replacement to prevent pricey downtime.

How Can I Train Staff for Effective Upkeep Practices?

To educate staff for efficient upkeep techniques, one can apply hands-on workshops, establish complete manuals, motivate mentorship programs, and carry out normal assessments to examine skills and knowledge, making sure all staff members understand maintenance procedures thoroughly.

What Are the Environmental Regulations for Aluminum Foundries?

Aluminum factories go through numerous ecological laws, including emissions control, waste administration, and resource conservation. Compliance assurances very little environmental effect, promoting sustainability while sticking to local, national, and international environmental requirements and guidelines.

Just How Do Shops Handle Waste and Recycling of Light weight aluminum?

Shops take care of waste and recycling by applying systems for accumulating scrap light weight aluminum, making use of innovative splitting up modern technologies, and teaming up with reusing centers to ensure effective recovery processes, thus reducing environmental influence and advertising sustainability within the market.

What Are the Costs Linked With Carrying Out Advanced Technologies?

Applying sophisticated innovations in foundries sustains considerable costs, including first financial investment, training, and maintenance expenses. Nonetheless, the lasting benefits, such as boosted effectiveness and decreased waste, frequently warrant these expenses, resulting in boosted profitability.

Regular maintenance plays a crucial role in the efficient procedure of aluminum factories. In light weight aluminum shops, these methods enable drivers to prepare for devices failings prior to they happen, thus reducing unexpected downtimes and maximizing operational effectiveness. Making use of advanced innovation has come to be increasingly necessary for light weight aluminum foundries aiming to boost functional performance. Common indications of devices wear in light weight aluminum informative post foundries include unusual sounds, decreased effectiveness, boosted resonance, overheating components, leaks, and visible rust. Applying sophisticated modern read what he said technologies in factories sustains significant costs, including first investment, training, and maintenance costs.